LIST OF EQUIPMENTS

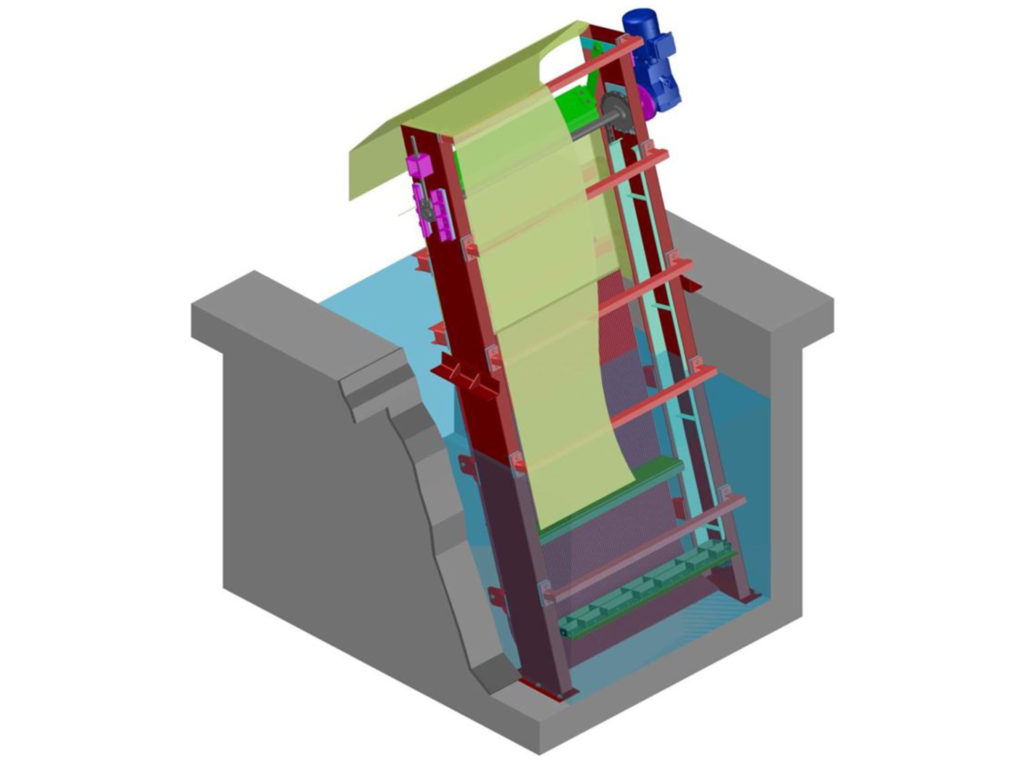

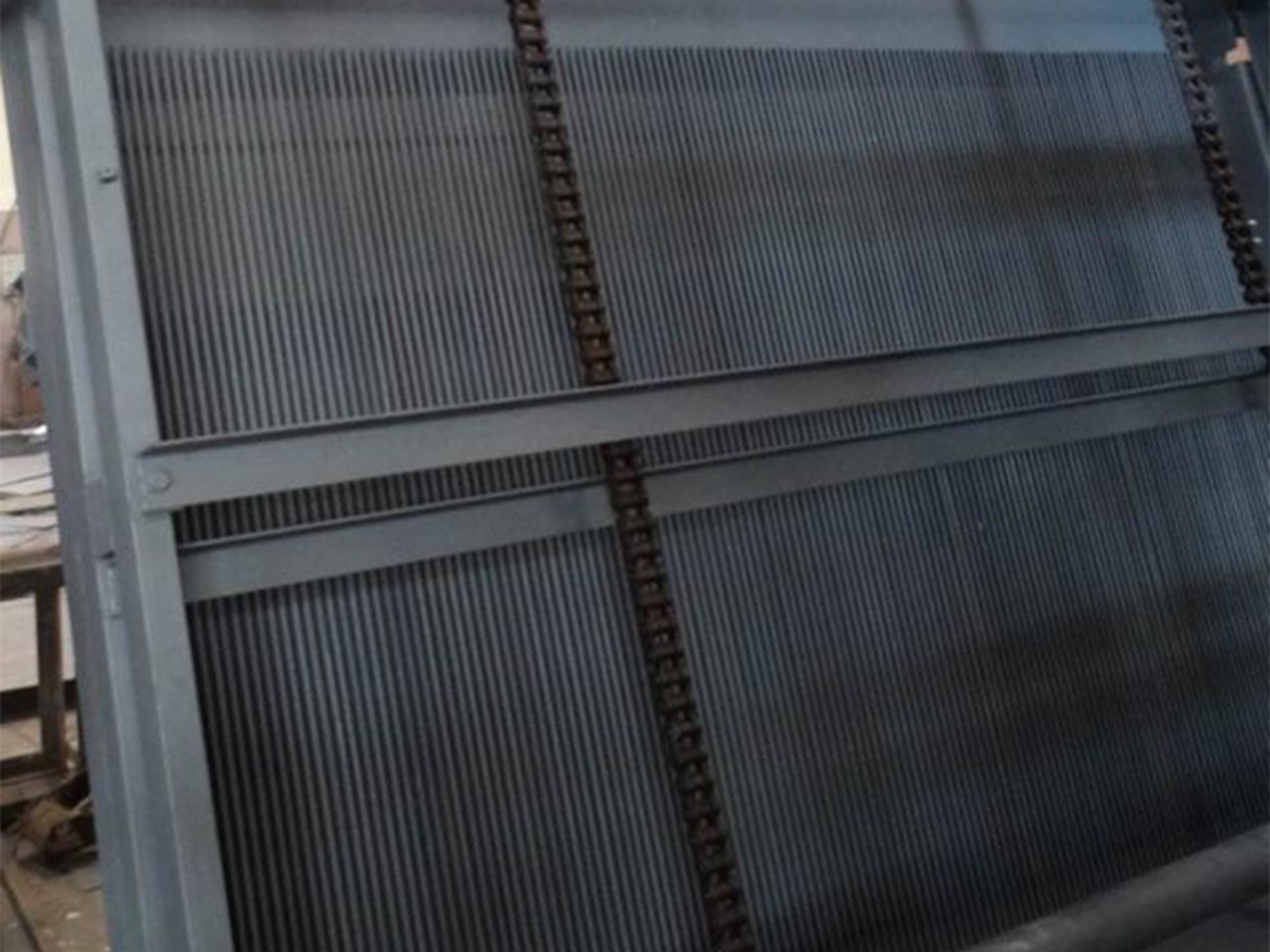

Manual and Mechanical Screens

We Manufacture Manual and Mechanical Bar screens 3 meters wide and 15 meters dept .

Single Rake Screen

Multi Rake Screen

Grit removal Mechanism

Grit removal is the process used to remove sand, silt and grit from water.

Grit (and sand) removal is often found in the headworks of wastewater treatment plants (WWTP). Grit removal can also be used to remove sand from river water intakes prior to processing for potable water, use in industrial applications to remove fine abrasives, as well as being used to remove grit entrained in sludge.

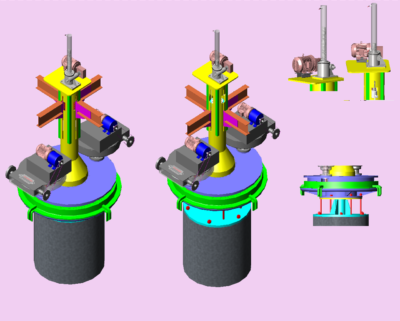

Clarifiers and Clariflocculators

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. A clarifier is generally used to remove solid particulates or suspended solids from liquid for clarification and/or thickening.

Clariflocculator is a combination of flocculation and clarification in a single tank. It has two concentric tanks where inner tank serves as a flocculation basin and the outer tank serves as a clarifier.

We manufacture Central Driven Clarifiers upto 45M dia(Shaft/Cage Driven.)

We manufacture Peripheral Driven Clarifiers upto 60M dia.

We manufacture Central Driven Clariflocculators upto upto 35M dia(Shaft/Cage Driven).

We manufacture Peripheral Driven Clariflocculators upto 65M dia.

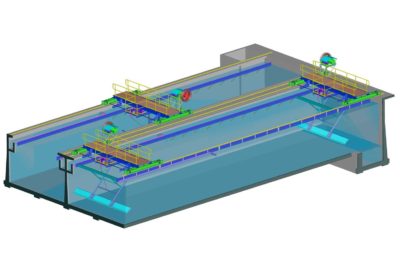

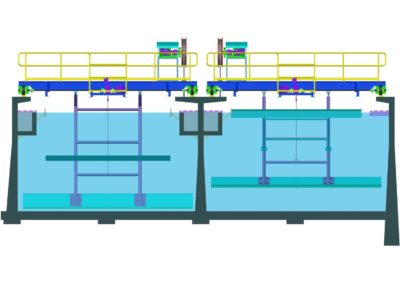

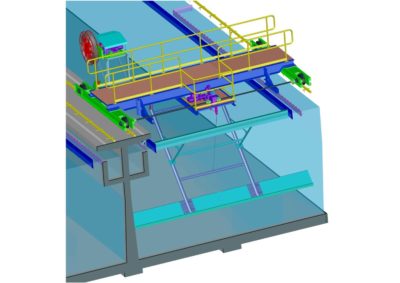

Rectangular Clarifiers

The selection of type of primary clarifier depends on:

- Regulation and preference of regulatory authorities

- Size of installation

- Local site condition

The advantages and disadvantages of rectangular clarifiers over circular clarifiers are summarized below:

- Advantages:

- Occupy less space when multiple units used

- Provide longer travel distance for settling to occur

- Less short circuiting

- Disadvantage:

- Possible dead corners

- Sensitive to flow surges

- Restricted in width by collecting equipment

Higher maintenance costs of sprocket, chains & flights

Both rectangular and circular configurations have been commonly used in clarifier basins. The relative merits of the two have been discussed at length for decades. Historically, the selection of rectangular versus circular clarifiers has been based on past experience and the preference of the design engineer or design company. Initial wastewater treatment plant designs in the United States were reasonably balanced between rectangular and circular when collector or scraper systems were designed from steel. With the introduction of biological treatment, corrosion became more of a concern and circular clarifiers became more popular

Sludge Thickener

Sludge Thickening is a process in which the solids concentration is increased and the total sludge volume is correspondingly decreased, but the sludge still behaves like a liquid instead of a solid. Thickening commonly produces sludge solids concentrations in the 3% to 5% range, whereas the point at which sludge begins to have the properties of a solid is between 15% and 20% solids. Thickening also implies that the process is gravitational, using the difference between particle and fluid densities to achieve the compaction of solids.

The advantages of sludge thickening in reducing the volume of sludge to be handled are substantial. A sludge with 1% solids thickened to 5% results in an 80% volume reduction (since 5% = 1/20). A concentration of 20% solids, which might be achieved by mechanical dewatering results in a 95% reduction in volume, with resulting savings in treatment, handling, and disposal costs.

We Have lifting device incorporated in our equipment which helps in the smooth working of the device

We manufacture Telescopic Sludge Draw Off Valves.

We manufacture Surface Aerators (Fixed and Floating).

We manufacture Agitators/Flash Mixers.

We manufacture Dissolved Air Flotation Unit.

We manufacture Lamella Clarifiers.

We manufacture API Oil Separators.

We manufacture Oil and Grease Skimmers.

We manufacture HRSCC- high rate solid contact clarifier..

We manufacture Aerated grit chamber.

Claritube Settlers

Tube settlers are gravity settlers wherein the settler is provided with tubes to increase the surface area of separation of solids from the liquid. The tubes are placed in an inclined fashion.

A tube settler is made up tubular channels that are placed adjacent to each other. These are placed at 60 degrees and combined to increase the effective settling area of particles. The settling area of the particles is made in such a way that it is less deep than that of the conventional clarifier.

Sand Traps , Telescopic Valve

A sand trap provides for the quick removal of settleable (sand) particles from the water, in order to prevent damage to mechanical components in the water treatment plant. A sand trap is usually carried out as a concrete gutter, where the waste water flows through while sand particles settle.

Telescopic Valve is used to get sludge sampling

OUR CLIENTELE

It is a privilege working with some of the well known companies.We view our clients as partners and work collaboratively with them to achieve the best.We work both diligently and intelligently to ensure that the needs of our clients comes first .